| 6151 Portage Road, Kalamazoo, MI | Coordinates Lat N 42:13':699" Lon W 85:33':456" |

The web site of the museum

|

|

|

The Kalamazoo air zoo. The complex is two buildings. The main building has a more pristine, wide open and polished look, and is more targeted to families with children of all ages, the second, is behind the main parking lot and on the air field. it will appeal to the more serious airplane buff. It has an extensive collection of engines, and planes in excellent condition. As with all of these types of museums. because of the close packing of the aircraft a good photo is impossible.

|

1

|

|

|

|

|

|

|

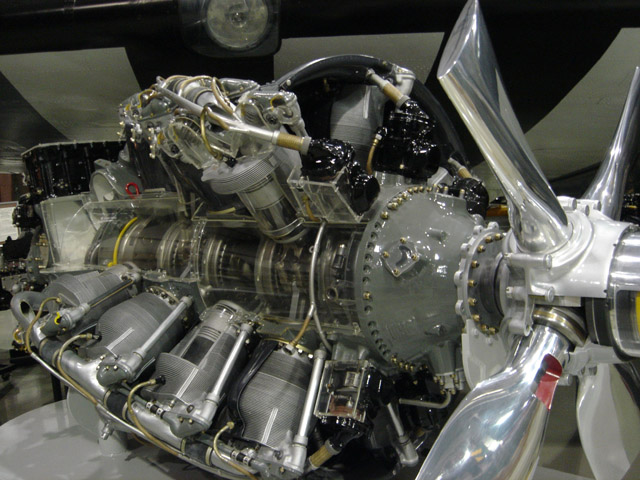

R-4360 WASP MAJOR Pratt & Whitney Corp. East Hartford, Conn. In 1940 the Pratt & Whitney Corp. started development of what would prove to be the largest, most complex, and most powerful aviation piston engine ever to reach production status, the R-4360 Wasp Major. Designed to power the next generation of piston-engined aircraft that were then on the drawing boards, the advent of the jet engine meant the Wasp Major actually was installed in comparatively few production aircraft. These included the Boeing B-50 Superfortress, Convair B-36 Peacemaker, Martin AM-1 Mauler, Douglas C-124 Globemaster, and Boeing C-97 Stratocruiser. The Wasp Major was also used in a number of experimental aircraft that did not reach production status, such as the Republic XP-72, Goodyear F2G, and Northrup XB-35 Flying Wing. Despite its size and complexity, the Wasp Major was a reliable engine in flight, although it could be troublesome on the ground. It was one of the few engines ever built that could be shut down in perfect operating condition and then have something wrong with it the next time it was started! In the B-36, which used six of these engines, the Air Force developed a series of checks so extensive that a shutdown procedure tool six hours and the start-up took four hours This is a B QEC (Quick Engine Change) unit for a Boeing - Superfortress designed to reduce the downtime needed It to was replace a bad engine on the B-50. THIS WASP MAJOR ENGINE |

|

|

|

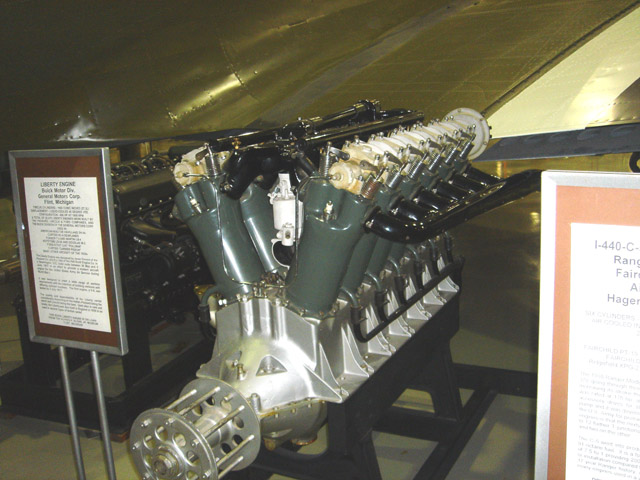

LIBERTY ENGINE TWELVE CYLINDERS - 1650 CUBIC INCHES (27.3L) DISPLACEMENT - LIQUID-COOLED 45 DEGREE VEE CONFIGURATION - 400 HP AT 1800 RPM A TOTAL OF 20,478 LIBERTY ENGINES WERE BUILT BY THE PACKARD, LINCOLN & FORD COMPANIES, AND THE BUICK DIVISION OF THE GENERAL MOTORS CORP. USED IN: The Liberty Engine was designed by Jesse Vincent of the Packard Co. and E.J. Hall of the Hall-Scott Engine Co. in a Washington, D.C. hotel suite between 30 May and 4 June, 1917 in an effort to provide a modern aircraft engine for the United States Army Air Service during World War I. It was designed to meet a wide range of wartime requirements with the intention of building versions with differing cylinder numbers. The first engine, a V- 8, was tested by 3 July 1917! The quality and dependability of the Liberty varied considerably depending on the maker--Packard being the worst and Lincoln being the best. Used also in cars and boats, the Liberty was also built in England in 1938 to be used in several types of British tanks! THIS BUICK LIBERTY ENGINE IS ON LOAN

|

|

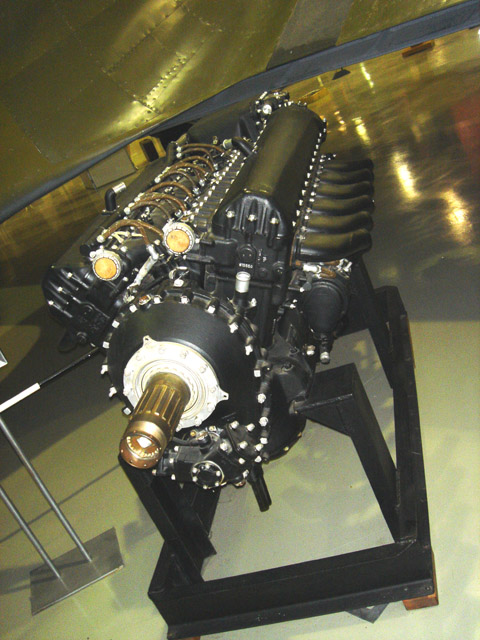

V-1650-7 MERLIN ENGINE TWELVE CYLINDERS - VEE CONFIGURATION USED IN: Packard Motor Car Company of Detroit, Michigan began aircraft engine production in 1915. During World War I, Packard had produced 6000 units of the famous V-12 Liberty engines. Packard began production of the Merlin in September 1940. under a British contract. In 1942, production began for the Packard-Merlin engine to be installed in the famous P-51 Mustang aircraft. (The original Mustangs were equipped with General Motors' V1710 Allison engines of 1320 hp. The Allison engine could not maintain power at high altitude, thus the Mustang was converted to the more powerful Merlin engine.) Continental Motors was a subcontractor to provide additional needed engines for the war time demands. The Muskegon company built 800 of the units making this example a very rare engine indeed! Other companies producing the Merlin were: Rolls Royce (150,000). U.S. Packard (54,700), and Australian Commonwealth Aircraft Corp. (100). THIS MERLIN ENGINE WAS DONATED BY |

|

|

A few comments about the Museum: A very nice museum. the entrance is a little spendy at $20 / head adult to get in. In the main facility there are several rides to go on, which I would expect help offset some of the entrance fee. the Jet flight simulator is a 6 axis hydraulic simulation pod capable of rolls, dives, flips and any other aerial maneuvers. It is dizzying to say the least. It would be nice if the Museum split the admission cost to 2 type, one to do the whole thing, and another just to see the aircraft in the hangar, near the air strip. If you have never been before, do it all !

|

|

| Back to Historical Markers | |

| Back to USA |